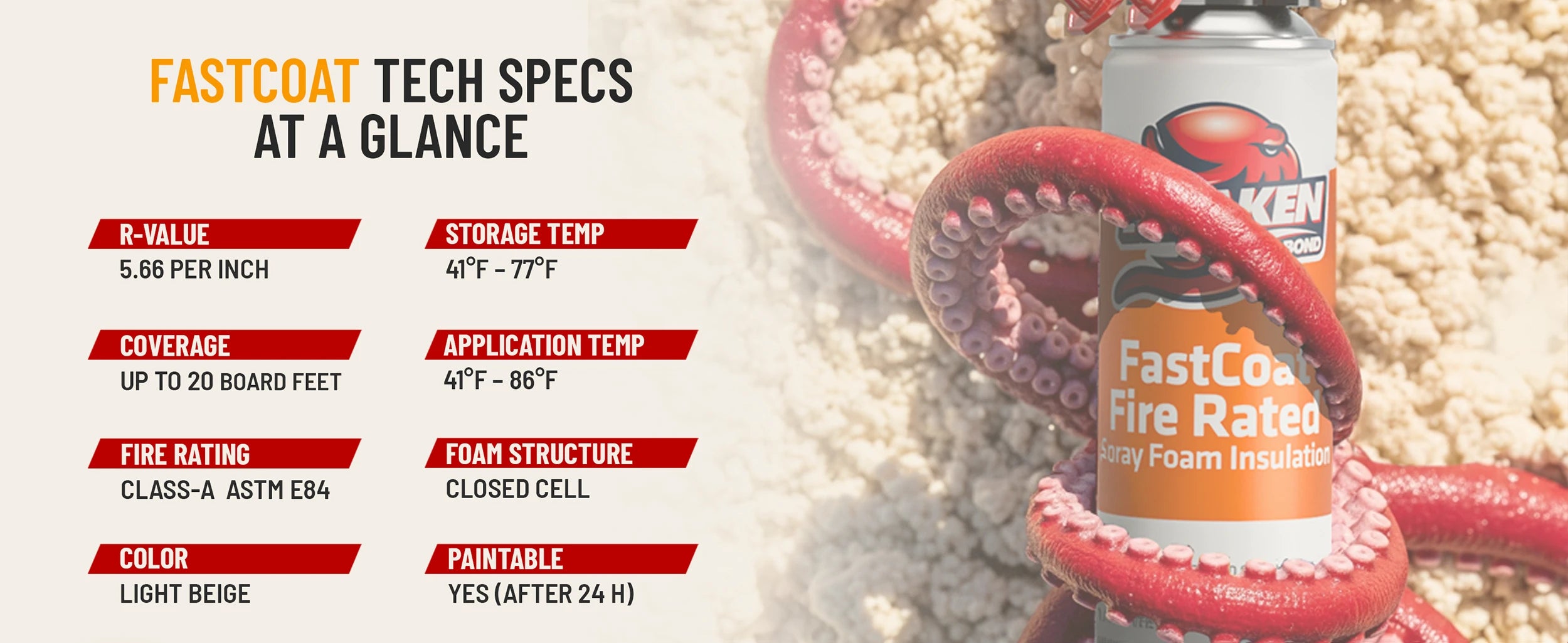

- Exceptional Thermal Performance: Achieve superior energy efficiency with a thermal conductivity of 0.025 W/m.K (DIN 52612) and an impressive R-value of 5.66 per inch. This closed-cell foam minimizes heat transfer, keeping your indoors comfortable year-round.

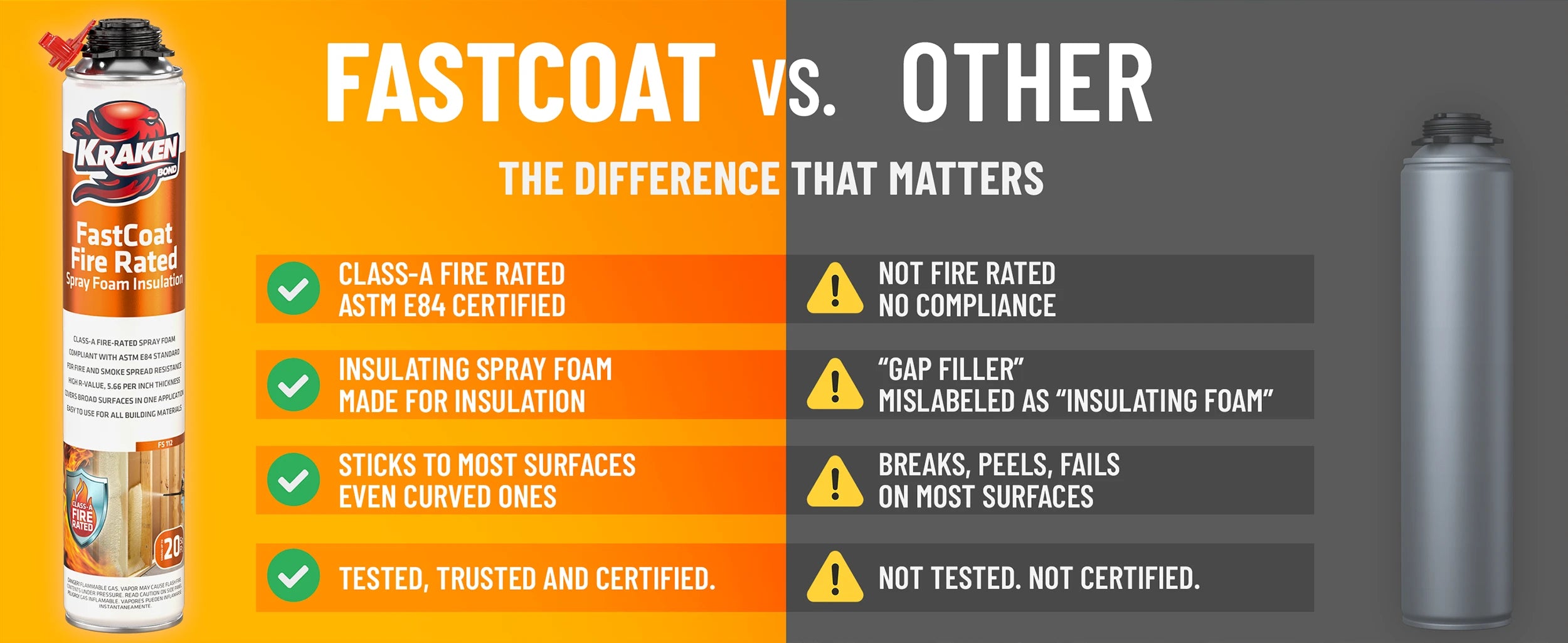

- Class A Fire Rated (ASTM E84): Engineered for enhanced safety, FastCoat boasts a Flame Spread of 5 and Smoke Development of 15, meeting stringent fire resistance standards.

- Seamless, Monolithic Application: Provides a continuous, gap-free insulation layer that eliminates thermal bridges and dew points, ensuring optimal insulation performance. It can be applied easily to uneven and hard-to-reach surfaces where traditional materials are impractical.

- High Yield & Cost-Effective: One can yields up to 20 board feet with a 1-inch thickness when applied correctly, offering excellent coverage and value.

- Strong Adhesion: Bonds excellently to all common building materials without the need for mechanical fasteners.

- Moisture & UV Resistance: The cured foam is moisture-resistant, helping to prevent mold growth. For outdoor applications, it is overpaintable and should be painted or coated to protect against UV discoloration.

- Ozone-Friendly: Does not contain propellant gases harmful to the ozone layer.

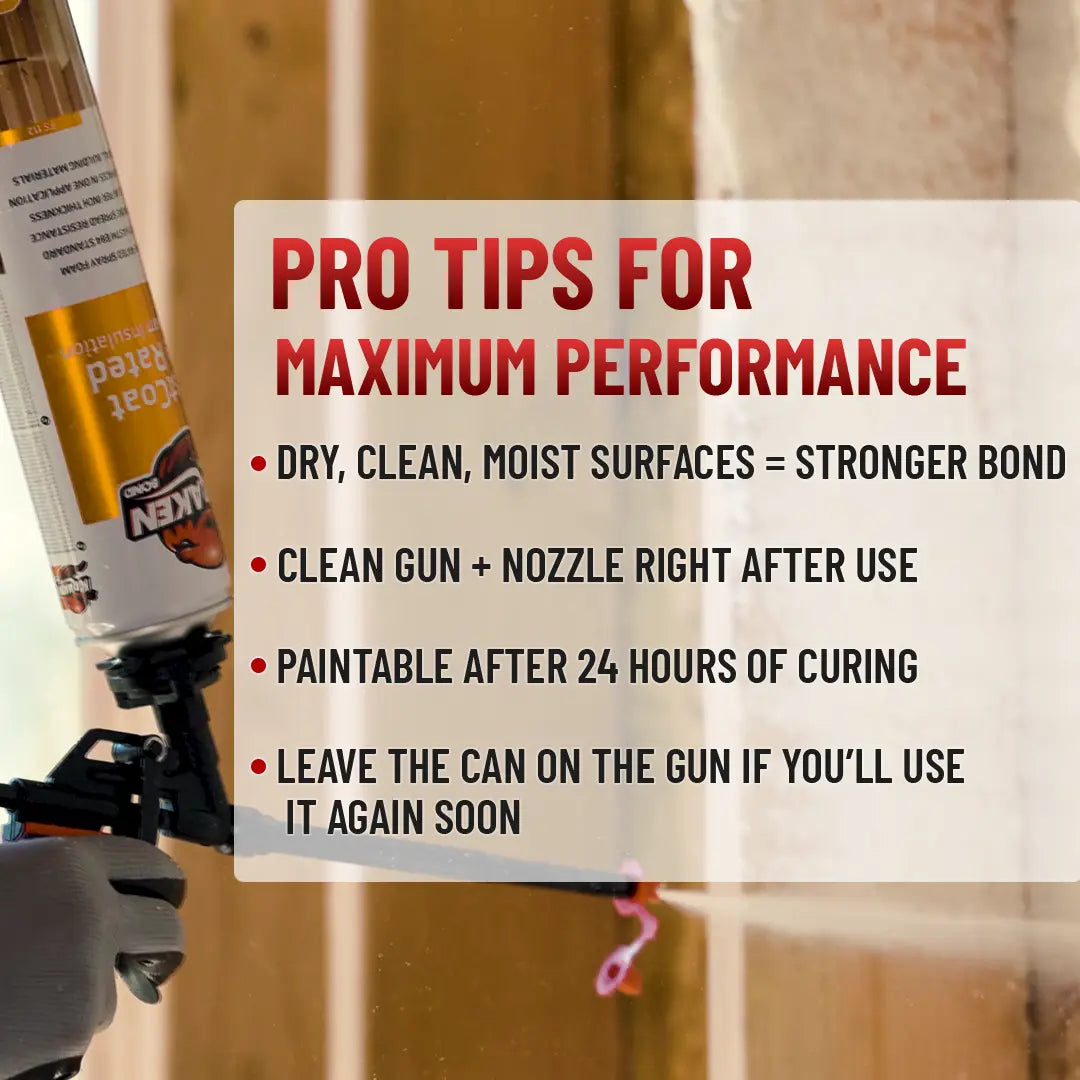

- Fast Curing: Features a skin time of 5±2 minutes and a cutting time of ≤40 minutes, with full cure achieved in 24 hours.

- Acoustic Performance: Contributes to noise reduction with an acoustic insulation rating of 48.8 dB at 1600Hz (EN ISO 717-1). Helps foster a calmer, more comfortable environment for your home or business.

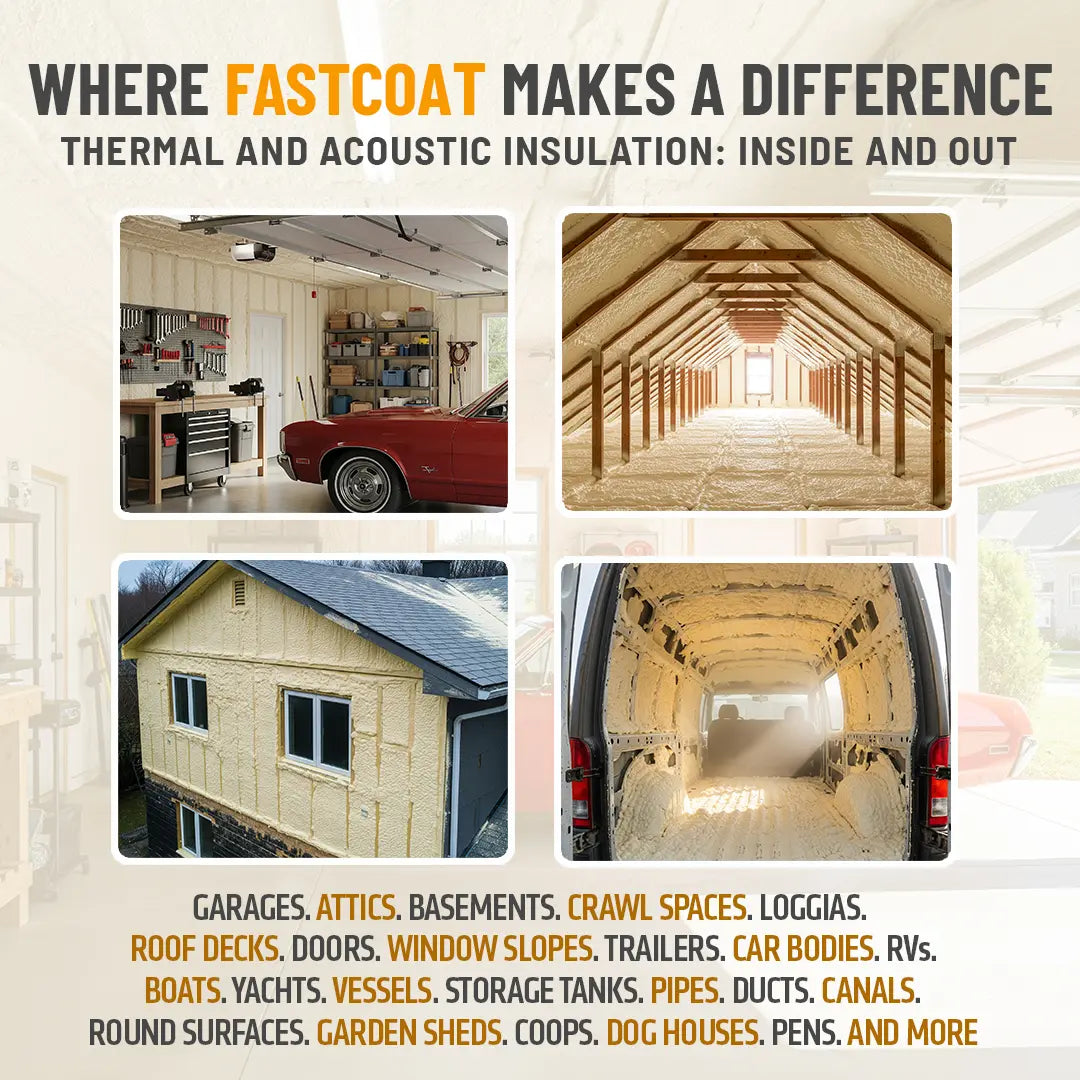

- Buildings & Houses: Roofs, attics, facades, foundations, basements, floors, interior walls, inter-floor overlappings, interior partitions, ceilings, and cellars.

- Structural Elements: Balconies, loggias, doors, window slopes, pipes, canals, and tank-like round surfaces.

- Vehicles: Car bodies, car trailers, boats, yachts, vessels, and all types of sea vehicles.

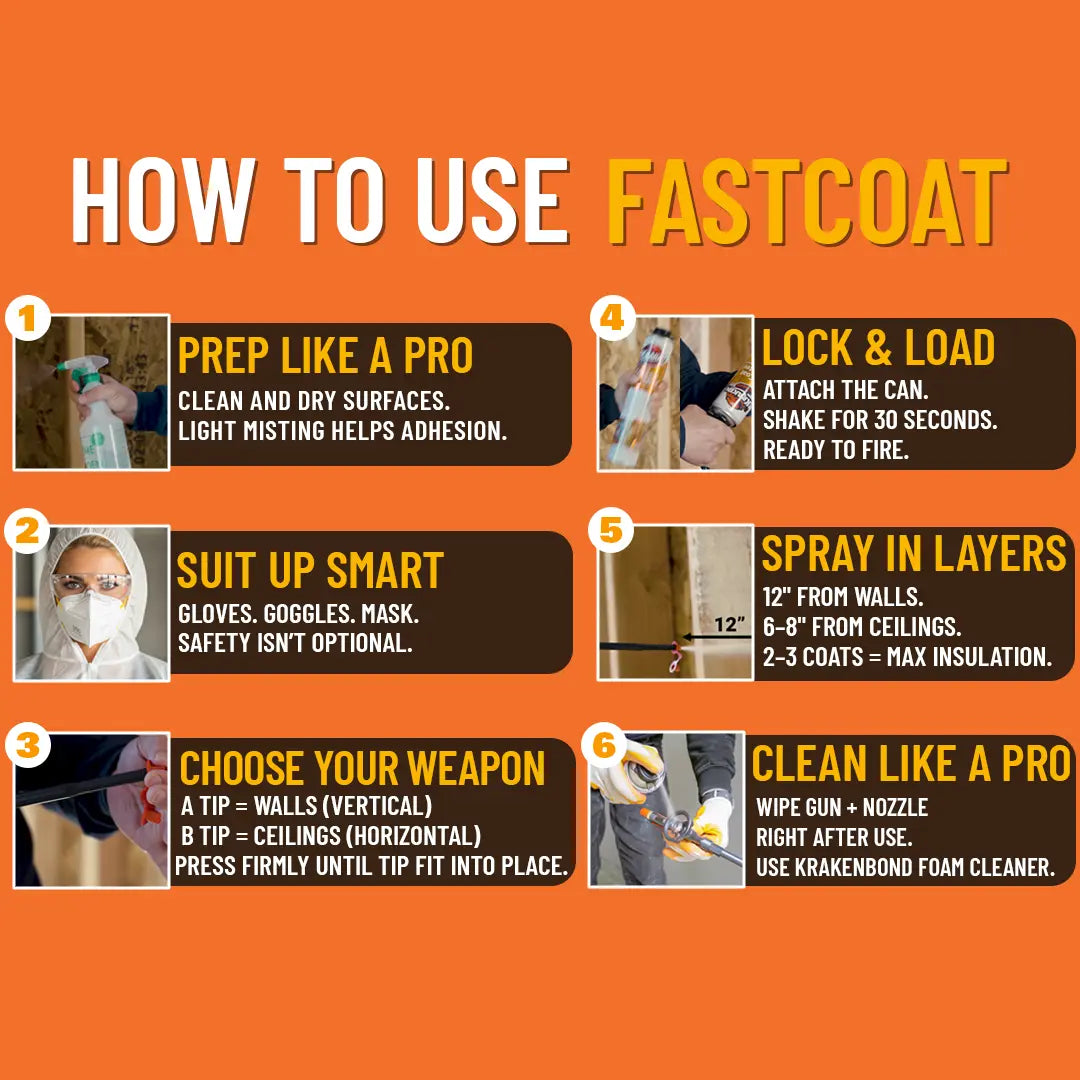

1. PREP LIKE A PRO: Make sure the surface is clean, dry, and free of dust, oil, or debris. For temperatures above 32°F, lightly mist the surface with water. This simple step is crucial for improving adhesion and speeding up the curing process, ensuring you get the best coverage from your foam.

2. SUIT UP SMART: Safety isn’t optional. Wear gloves, goggles, and mask to protect yourself while working with the foam.

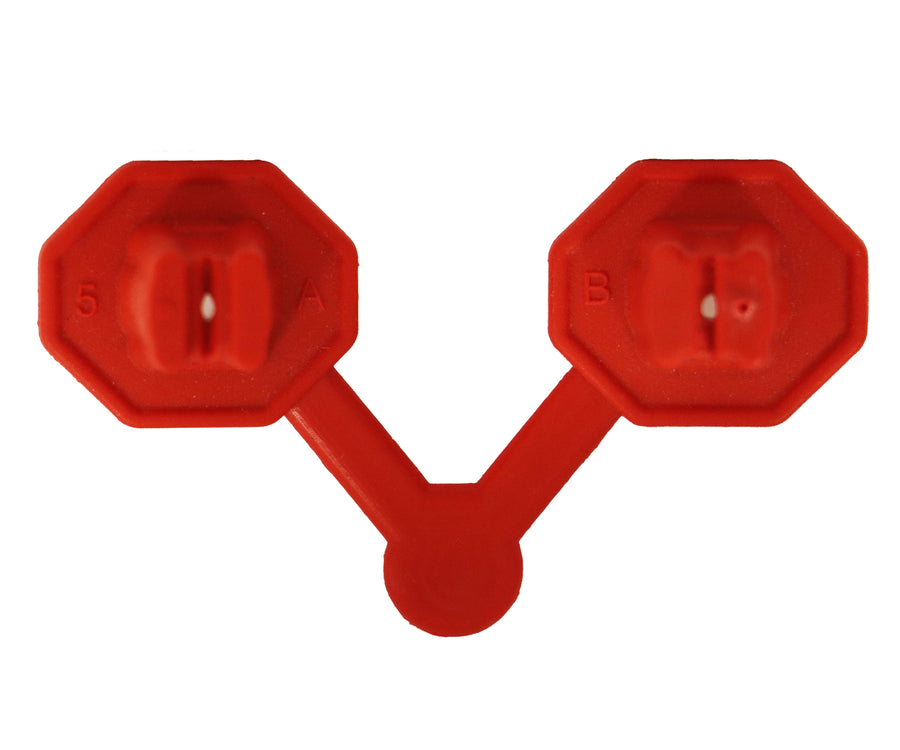

3. CHOOSE YOUR WEAPON: Select the right nozzle for your project:

- Tip A – For vertical surfaces like walls and gaps.

- Tip B – For horizontal surfaces like ceilings.

Press firmly until the tip clicks securely into place.

4. LOCK & LOAD: Bring the can to room temperature (around 68°F) for at least 24 hours before use. This ensures stable pressure, smooth spraying, consistent foam expansion, and a denser, higher-quality application.

- Shake vigorously for at least 30 seconds before spraying to ensure a consistent and dense foam.

- If the can is too cold or too hot, immerse it in warm or cold water, or leave it at room temperature until it reaches room temperature.

Attach the can & ready to fire!

5. SPRAY IN LAYERS:

- Hold the can upside down during application.

- Maintain the right distance : 12–18 inches from walls and 6–8 inches from ceilings.

- Apply in thin layers : For a total thickness of 2 inches, use at least 3 layers. Avoid overfilling in one pass.

- Shake the can between applications for even, high-quality coverage.

6. CLEAN LIKE A PRO

- Wipe the gun and nozzle immediately after use.

- Use Kraken Bond Foam Cleaner for fresh foam.

- Once cured, foam can only be removed mechanically.

- Protect cured foam from UV rays by covering it with plaster, paint, or another coating.

7. HELPFUL TIPS:

- Every can comes with two replacement tips for convenience.

- For consistent results, test spray on a scrap surface first.

- Contact support promptly for troubleshooting if coverage or expansion seems below standard.

- Chemical Structure: Polyurethane Pre-polymer

- Curing Mechanism: Moisture

- Foam Color: Cream

- Dimensional Stability: ±10%

- Compression Strength: 4.35 PSI (DIN 53421)

- Ideal Can Temperature: +41°F to +86°F

- Application Temperature: +41°F to +86°F

- Heat Resistance: −103°F to +239°F

- Curing is dependent on temperature and humidity.

- Do not use in poorly ventilated spaces or areas exposed to direct sunlight without protection.

- Lower temperatures can decrease yield and curing time.

- Store properly in the original container; shelf life is 18 months.

- Contains diphenylmethane-4,4'-diisocyanate. Use in a well-ventilated environment and wear protective gloves. Keep away from direct sunlight and temperatures above 122°F.

Featured by Top Creators

Don’t Miss Our Spray Foam Guns & Accessories

View allApplication Areas

Walls

Ceilings

Exterior Walls

Garage

HVAC Ductwork

Sheds

Pools

Trailers

Vans

Your Moments, Our Products

FAQs

FastCoat is a professional-grade, closed-cell polyurethane spray foam that expands on contact to fill gaps, cracks, and cavities. As it cures, it forms a dense, monolithic air-sealing barrier that delivers high thermal insulation, reduces sound transfer, and prevents air and moisture infiltration.

Unlike traditional materials like fiberglass, mineral wool, or EPS/XPS boards, FastCoat creates a seamless layer with no joints or weak points—making it ideal for energy-efficiency upgrades and long-term durability.

It’s suitable for residential, commercial, and industrial applications; including roofs, attics, basements, interior walls, crawl spaces, ceilings, and even vehicles such as trailers, boats, and yachts.

Each FastCoat kit includes closed-cell foam cans, an application gun, foam cleaner, and full safety gear (goggles, gloves, protective coverall).

Coverage varies by kit size:

- 12-Can Kit: ~240 sq ft at 1" thickness (≈ 240 board feet)

- 24-Can Kit: ~480 sq ft at 1" thickness (≈ 480 board feet)

At 2" thickness, FastCoat delivers an R-Value of 11.32 under standard conditions.

Yes, as long as the area is isolated and well-ventilated. Avoid staying in the immediate work zone during spraying.

FastCoat skins in about 5 minutes, can be trimmed after 40 minutes, and fully cures in 24 hours.

You may re-enter after 12 hours of ventilation (sensitive individuals may require up to 24 hours).

Once cured, the foam is ready for paint or coating.

FastCoat adheres to wood, drywall, masonry, concrete, metal, and rigid foam boards.

Surfaces must be clean, dry, and free of dust, oil, or rust.

For outdoor applications, always coat cured foam with UV-resistant paint or coating.

For best performance, the can should be around 68°F (20°C).

Apply when ambient temperature is between 41°F and 86°F (5–30°C).

Shake the can thoroughly before use. Attach the correct nozzle to the foam gun:

- Use Nozzle A for vertical surfaces

- Use Nozzle B for ceilings

Hold the can upside down and spray from 12–18 inches for walls or 6–8 inches for ceilings. Apply in thin passes until the desired thickness is achieved.

FastCoat provides an R-Value of ≈ 5.66 per inch (R-11.32 at 2").

Operating range: −103°F to 239°F (−75°C to 115°C).

With proper UV and moisture protection, service life is 25–30 years.

It means FastCoat passed the ASTM E84 fire test, meeting common U.S. building code requirements for residential and commercial projects.

FastCoat is Class A fire-rated and offers high flame-spread resistance.

However, like all spray foams, building codes may require it to be covered with a protective finish such as paint or gypsum board.

Yes. Its closed-cell structure blocks moisture infiltration and inhibits mold/mildew growth.

A mild odor may occur during spraying and typically dissipates within 24 hours with proper ventilation.

Yes. After full cure (≈ 24 hours), it can be painted or coated for UV protection and improved aesthetics.

Stored upright between 41°F and 77°F (5–25°C), shelf life is 18 months.

Yes, long-term UV exposure can discolor or degrade cured foam.

Always paint or coat outdoor applications.

Avoid storing below 41°F (5°C) or above 77°F (25°C).

Keep away from heat sources and direct sunlight.

Uncured foam can be removed with Kraken Foam Cleaner.

Once cured, mechanical removal is required.

FastCoat is a professional-grade, closed-cell polyurethane spray foam that expands on contact to fill gaps, cracks, and cavities. As it cures, it forms a dense, monolithic air-sealing barrier that delivers high thermal insulation, reduces sound transfer, and prevents air and moisture infiltration.

Unlike traditional materials like fiberglass, mineral wool, or EPS/XPS boards, FastCoat creates a seamless layer with no joints or weak points—making it ideal for energy-efficiency upgrades and long-term durability.

It’s suitable for residential, commercial, and industrial applications; including roofs, attics, basements, interior walls, crawl spaces, ceilings, and even vehicles such as trailers, boats, and yachts.

Each FastCoat kit includes closed-cell foam cans, an application gun, foam cleaner, and full safety gear (goggles, gloves, protective coverall).

Coverage varies by kit size:

- 12-Can Kit: ~240 sq ft at 1" thickness (≈ 240 board feet)

- 24-Can Kit: ~480 sq ft at 1" thickness (≈ 480 board feet)

At 2" thickness, FastCoat delivers an R-Value of 11.32 under standard conditions.

Yes, as long as the area is isolated and well-ventilated. Avoid staying in the immediate work zone during spraying.

FastCoat skins in about 5 minutes, can be trimmed after 40 minutes, and fully cures in 24 hours.

You may re-enter after 12 hours of ventilation (sensitive individuals may require up to 24 hours).

Once cured, the foam is ready for paint or coating.

FastCoat adheres to wood, drywall, masonry, concrete, metal, and rigid foam boards.

Surfaces must be clean, dry, and free of dust, oil, or rust.

For outdoor applications, always coat cured foam with UV-resistant paint or coating.

For best performance, the can should be around 68°F (20°C).

Apply when ambient temperature is between 41°F and 86°F (5–30°C).

Shake the can thoroughly before use. Attach the correct nozzle to the foam gun:

- Use Nozzle A for vertical surfaces

- Use Nozzle B for ceilings

Hold the can upside down and spray from 12–18 inches for walls or 6–8 inches for ceilings. Apply in thin passes until the desired thickness is achieved.

FastCoat provides an R-Value of ≈ 5.66 per inch (R-11.32 at 2").

Operating range: −103°F to 239°F (−75°C to 115°C).

With proper UV and moisture protection, service life is 25–30 years.

It means FastCoat passed the ASTM E84 fire test, meeting common U.S. building code requirements for residential and commercial projects.

FastCoat is Class A fire-rated and offers high flame-spread resistance.

However, like all spray foams, building codes may require it to be covered with a protective finish such as paint or gypsum board.

Yes. Its closed-cell structure blocks moisture infiltration and inhibits mold/mildew growth.

A mild odor may occur during spraying and typically dissipates within 24 hours with proper ventilation.

Yes. After full cure (≈ 24 hours), it can be painted or coated for UV protection and improved aesthetics.

Stored upright between 41°F and 77°F (5–25°C), shelf life is 18 months.

Yes, long-term UV exposure can discolor or degrade cured foam.

Always paint or coat outdoor applications.

Avoid storing below 41°F (5°C) or above 77°F (25°C).

Keep away from heat sources and direct sunlight.

Uncured foam can be removed with Kraken Foam Cleaner.

Once cured, mechanical removal is required.