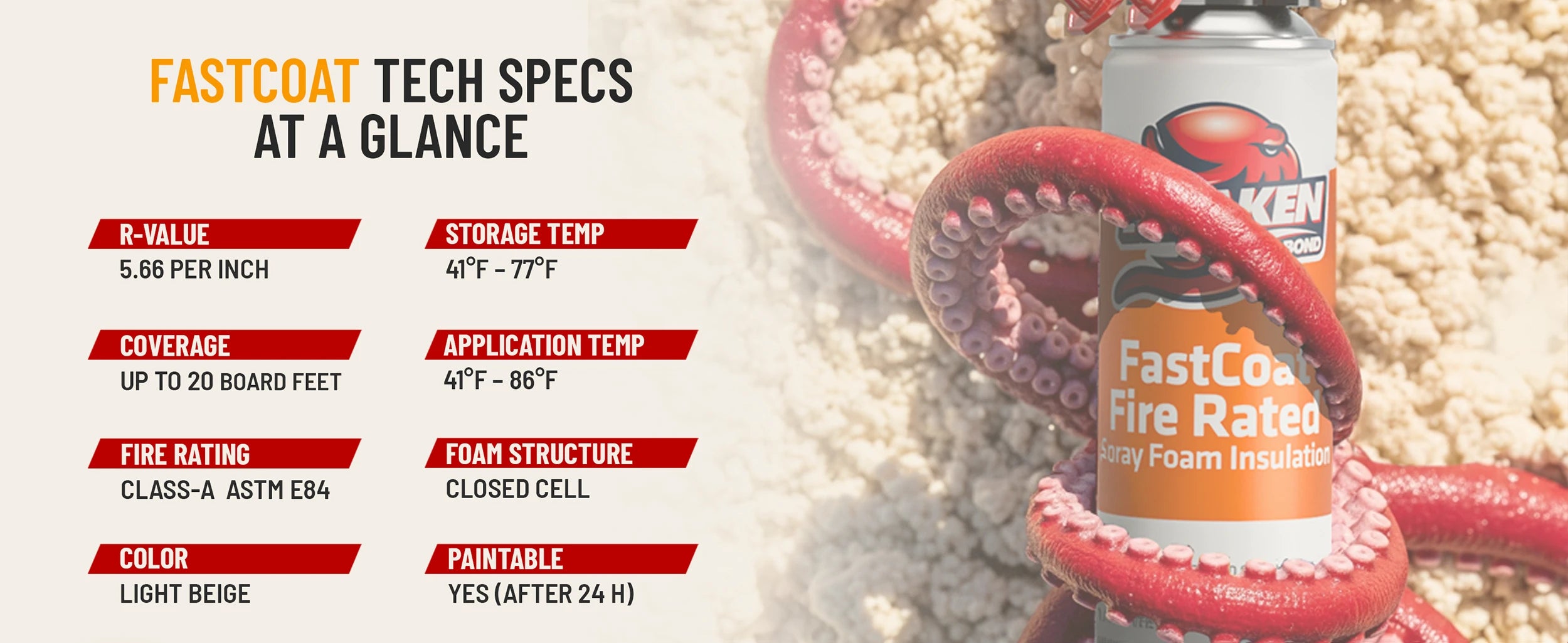

- Exceptional Thermal Performance: Achieve superior energy efficiency with a thermal conductivity of 0.025 W/m.K (DIN 52612) and an impressive R-value of 5.66 per inch. This closed-cell foam minimizes heat transfer, keeping your indoors comfortable year-round.

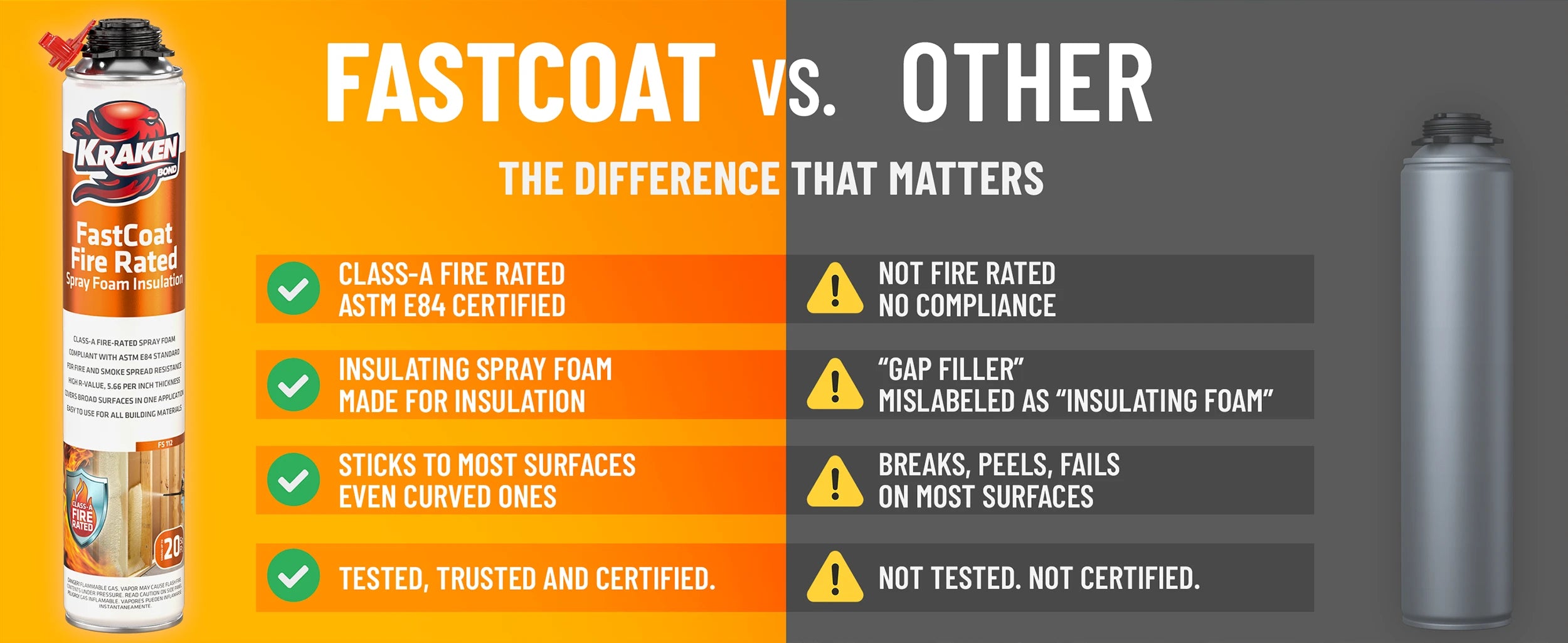

- Class A Fire Rated (ASTM E84): Engineered for enhanced safety, FastCoat boasts a Flame Spread of 5 and Smoke Development of 15, meeting stringent fire resistance standards.

- Seamless, Monolithic Application: Provides a continuous, gap-free insulation layer that eliminates thermal bridges and dew points, ensuring optimal insulation performance. It can be applied easily to uneven and hard-to-reach surfaces where traditional materials are impractical.

- High Yield & Cost-Effective: One can yields up to 20 board feet with a 1-inch thickness when applied correctly, offering excellent coverage and value.

- Strong Adhesion: Bonds excellently to all common building materials without the need for mechanical fasteners.

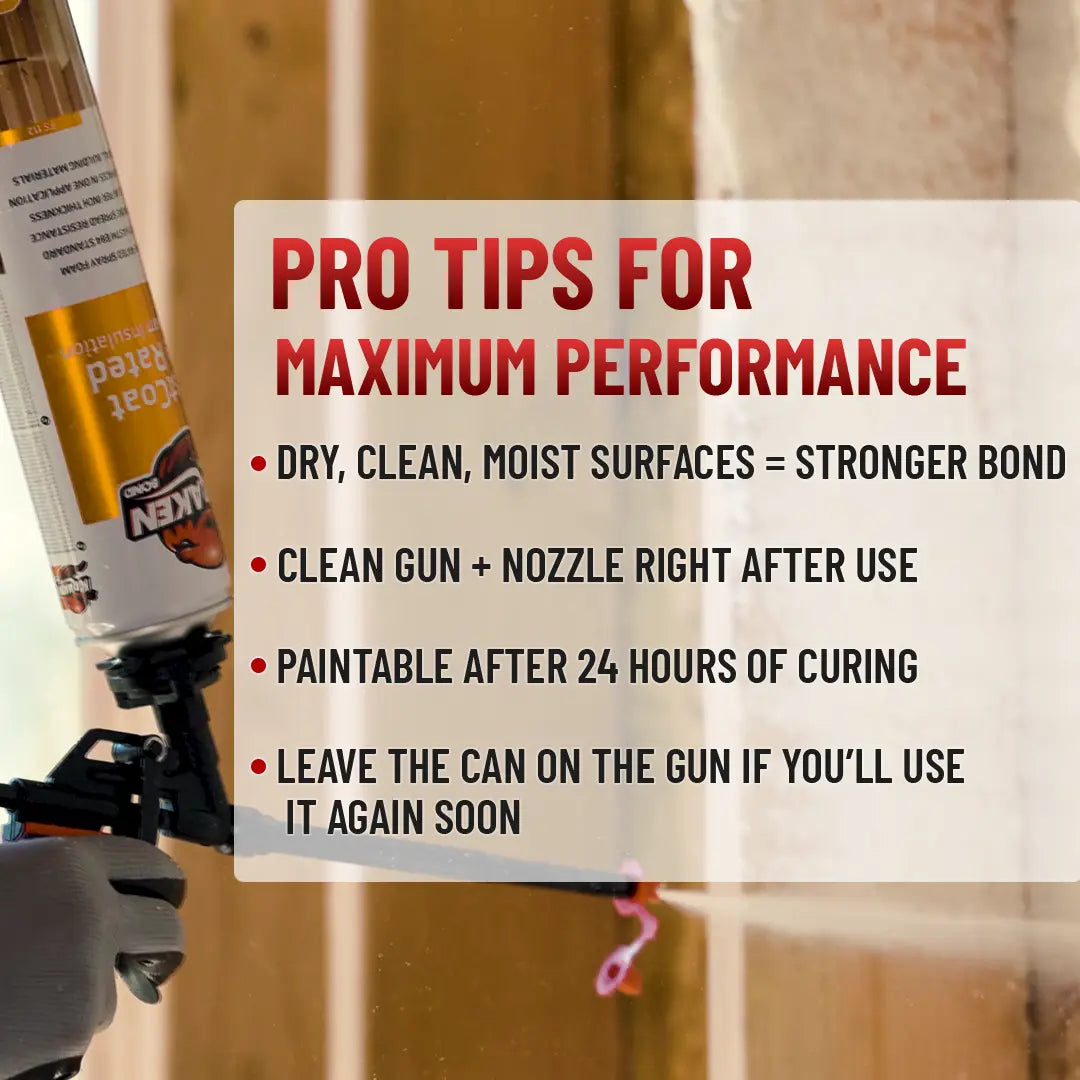

- Moisture & UV Resistance: The cured foam is moisture-resistant, helping to prevent mold growth. For outdoor applications, it is overpaintable and should be painted or coated to protect against UV discoloration.

- Ozone-Friendly: Does not contain propellant gases harmful to the ozone layer.

- Fast Curing: Features a skin time of 5±2 minutes and a cutting time of ≤40 minutes, with full cure achieved in 24 hours.

- Acoustic Performance: Contributes to noise reduction with an acoustic insulation rating of 48.8 dB at 1600Hz (EN ISO 717-1). Helps foster a calmer, more comfortable environment for your home or business.

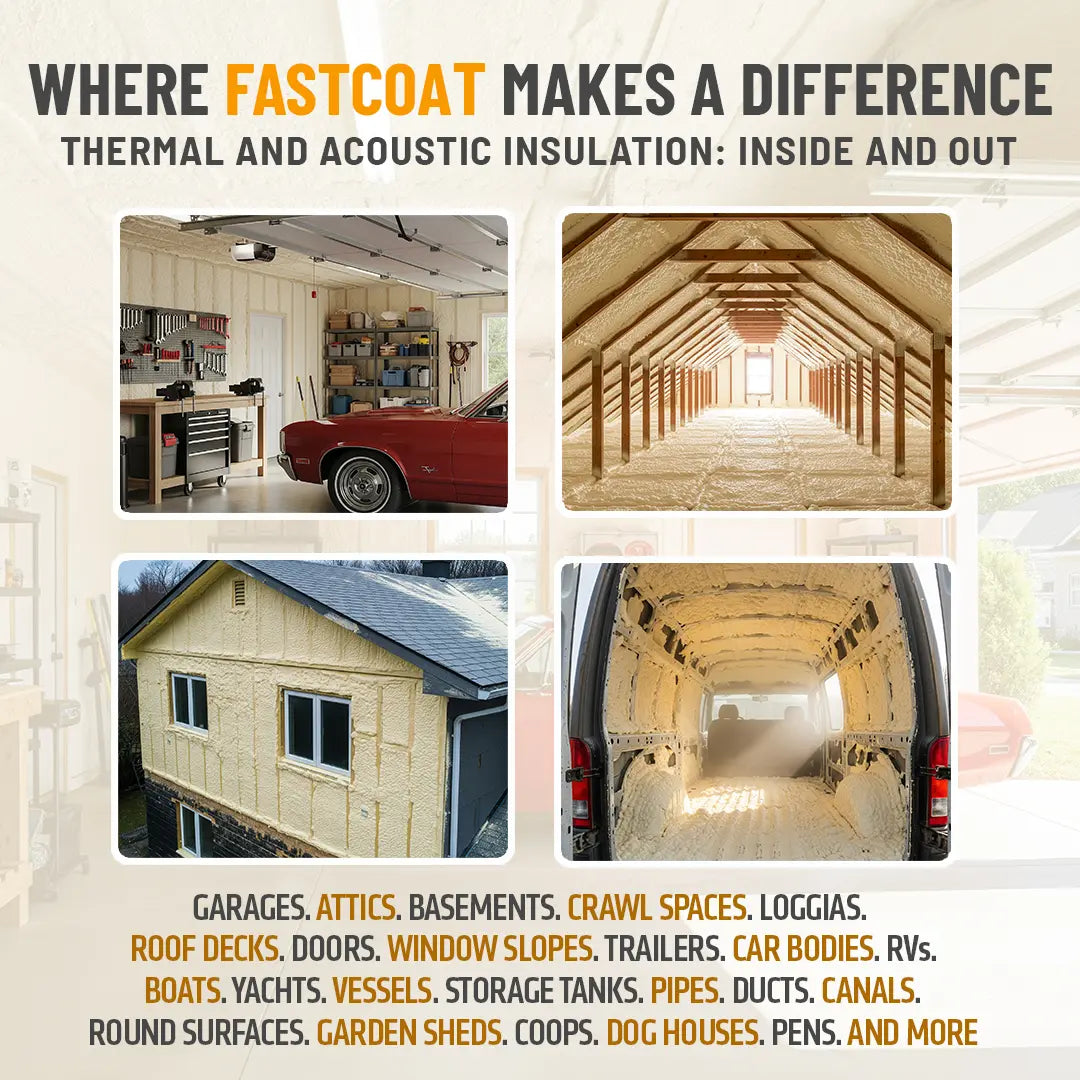

- Buildings & Houses: Roofs, attics, facades, foundations, basements, floors, interior walls, inter-floor overlappings, interior partitions, ceilings, and cellars.

- Structural Elements: Balconies, loggias, doors, window slopes, pipes, canals, and tank-like round surfaces.

- Vehicles: Car bodies, car trailers, boats, yachts, vessels, and all types of sea vehicles.

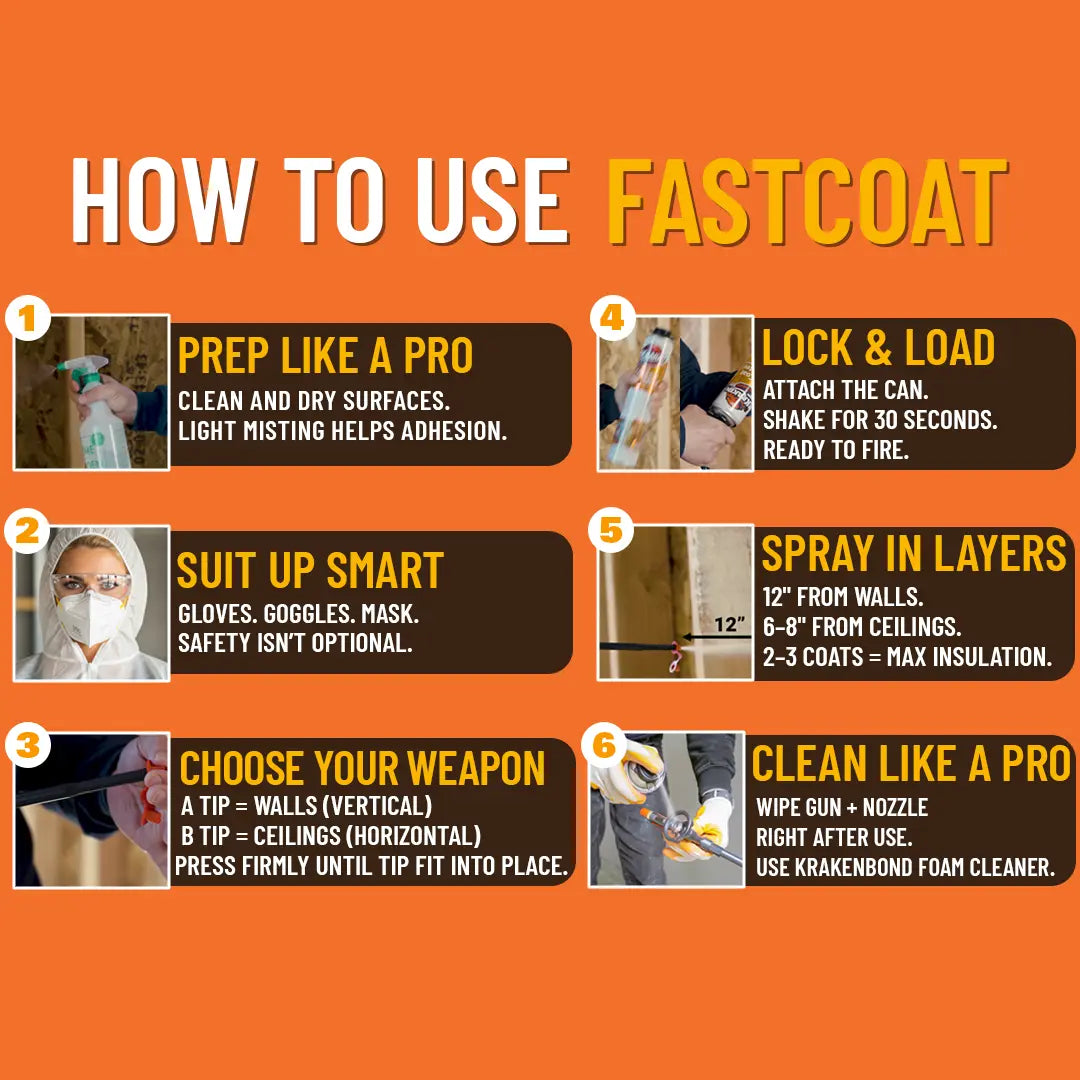

- Surface Preparation: Ensure substrates are clean, dry, and free of contaminants. Lightly sprinkle the working surface with water (at temperatures above 32°F) to improve adhesion and shorten curing time.

- Product Preparation: Bring the can to room temperature (+68°F is optimal) by leaving it in a room for at least 24 hours or immersing it in cold/warm water. Shake the can well before use.

- Foam Application: Attach the appropriate nozzle (Nozzle A for vertical, Nozzle B for ceiling applications) and screw the can onto an applicator gun. Always hold the can upside down during application.

- Spray from 12-18 inches for vertical applications.

- Spray from 6-8 inches for horizontal (ceiling) applications.

- Apply in layers, with a recommended total thickness of 2 inches achieved in a minimum of 3 layers for ideal insulation value. Do not fill entire gaps as the foam will expand.

- Finishing& Cleaning: Secure fully hardened foam against UV rays using plaster or paints. Clean fresh foam with foam cleaner; cured foam must be removed mechanically.

- Chemical Structure: Polyurethane Pre-polymer

- Curing Mechanism: Moisture

- Foam Color: Yellowish

- Dimensional Stability: ±10%

- Compression Strength: 4.35 PSI (DIN 53421)

- Ideal Can Temperature: +41°F to +86°F

- Application Temperature: +41°F to +86°F

- Heat Resistance: −103°F to +239°F

- Curing is dependent on temperature and humidity.

- Do not use in poorly ventilated spaces or areas exposed to direct sunlight without protection.

- Lower temperatures can decrease yield and curing time.

- Store properly in the original container; shelf life is 18 months.

- Contains diphenylmethane-4,4'-diisocyanate. Use in a well-ventilated environment and wear protective gloves. Keep away from direct sunlight and temperatures above 122°F.

Don’t Miss Our Spray Foam Guns & Accessories

View allYour Moments, Our Products

FAQs

20sq ft per can at 1" thick with an R-value of 5.66.

FastCoat is ASTM E84 Class A (sometimes called “Class 1”), meaning it achieved a Flame-Spread Index ≤ 25 and a Smoke-Developed Index ≤ 450 in third-party tunnel testing.

Yes. The ASTM E84 test is performed on fully cured samples, so the Class A rating applies to the product after installation and complete cure.

The International Residential Code (IRC) and International Building Code (IBC) accept ASTM E84 Class A materials for many wall, ceiling, and attic applications, provided all other code requirements (thickness, ignition barrier, thermal barrier) are met.

No. The Class A rating comes from the closed-cell chemistry and additives that limit flame spread and smoke—not the colorant itself.

Depending on the climate of the location you live in, the required R-value changes. For example, if you live in Zone 4 or 5, you will need a depth of 4-inches of this insulation installed in your 2X6 wall to reach R-20 with a clased-cell insulation that has an R-value of R-5 per inch of thickness. You can find R-value chart for the USA here.

Insulation Foam is measured in board feet. So a “20” kit will cover 20 sq. ft., 1-inch thickness.

It's closed-cell

Yes, it's flammable.

Temperature resistance is -103 F to 239 F.

The effective lifespan of Fastcoat Insulation Spray Foam is 25 years.

Yes, it's waterproof after appropriately cured.

You can be home after 12 hours of the application.

No, it doesn't.

After 6 hours.

Respirator, goggles, chemical-resistant gloves.

You can use it, but no need after the Fastcoat application.

R-Value is 5.66 per inch.

20 board feet at 1 inch thick of spray foam with an R-value of 5.66.

Yes, it works well for that. It can get into all the cracks and holes.

It is a medium to low density.

You can use it with spray foam gun. You'll also need spray foam gun cleaner or acetone to clean up any messes and prolong the applicator gun life.

Other spray foam guns may work with Kraken FastCoat, but for optimal performance, we recommend Kraken guns. For trusted products, including Kraken and compatible Stanley products, visit OneClickDIY.

No, it doesn't. Great stuff has there own special tip, and the directions with Kraken spray foam won't work.

Under a porch. it won't get wet

You can use it on the bottom side of the galvanized roof and shouldn’t expose it to sunlight.

Yes, it prevents heat. You can apply it to the bottom side of the gazebo. It would be better if you cover it with plywood, plasterboard, or similar products that keep it from the direct sunshine. You can paint it with black color if not possible to cover with the other materials.